The Drive Behind 3K Carbon Fiber for Automotive Parts

Share

The Drive Behind 3K Carbon Fiber for Automotive Parts

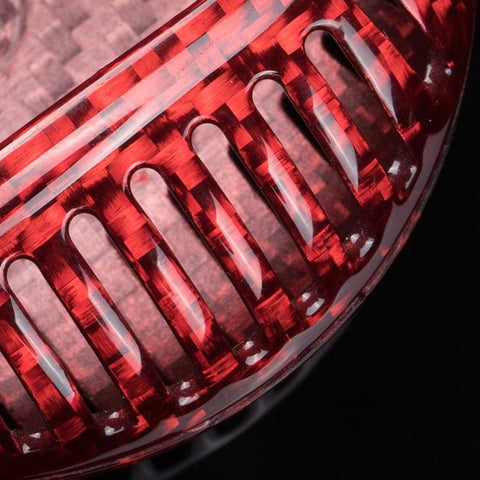

In the ever-evolving world of automotive engineering, the quest for performance, efficiency, and innovation drives manufacturers to seek out the best materials for their vehicles. Among the array of options, 3K carbon fiber has emerged as a top choice for crafting essential car parts. Let's explore the compelling reasons why 3K carbon fiber has become a go-to material for automotive components.

1. Strength-to-Weight Ratio:

Exceptional Strength: One of the most compelling reasons for choosing 3K carbon fiber for car parts is its outstanding strength. Despite its lightweight nature, 3K carbon fiber offers remarkable strength properties, allowing manufacturers to create parts that can withstand rigorous demands.

Reduced Weight: Pound for pound, carbon fiber is significantly lighter than traditional materials like steel or aluminum. This weight reduction translates directly to improved fuel efficiency, better handling, and increased performance. By incorporating 3K carbon fiber into car parts, manufacturers can achieve substantial weight savings without compromising on strength or durability.

2. Enhanced Performance:

Improved Acceleration and Handling: Lighter car parts made from 3K carbon fiber contribute to better acceleration and enhanced handling. The reduction in weight means that the engine has to work less to move the vehicle, resulting in quicker acceleration and improved responsiveness.

Enhanced Structural Integrity: 3K carbon fiber's impressive stiffness ensures that car parts maintain their shape and structural integrity even under extreme conditions. This stiffness is particularly beneficial for components like chassis parts, where rigidity is essential for optimal performance and safety.

3. Durability and Longevity:

Resistance to Corrosion: Unlike traditional metals, 3K carbon fiber is highly resistant to corrosion, making it an ideal choice for car parts that are exposed to harsh environments. This resistance ensures longevity and reduces the need for frequent replacements or repairs.

Impact Resistance: Car parts made from 3K carbon fiber exhibit excellent impact resistance, which is crucial for components like body panels and bumpers. They can withstand minor collisions and road debris without sustaining significant damage, contributing to the overall durability of the vehicle.

4. Customization and Design Flexibility:

Tailored Engineering: 3K carbon fiber offers engineers and designers a high level of customization and design flexibility. The material can be molded into complex shapes and forms, allowing for aerodynamic enhancements, intricate designs, and optimized performance characteristics.

Versatile Applications: From body panels to interior trims, 3K carbon fiber can be used in a wide range of automotive applications. Whether it's improving the exterior aesthetics of a sports car or enhancing the functionality of a luxury sedan, the versatility of 3K carbon fiber allows for endless possibilities.

5. Environmental Considerations:

Sustainability: As automotive manufacturers increasingly focus on sustainability, 3K carbon fiber offers an eco-friendly alternative to traditional materials. Its lightweight properties contribute to reduced fuel consumption and lower emissions, aligning with the industry's push towards greener technologies.

Recyclability: 3K carbon fiber can be recycled and reused, further reducing its environmental impact. This recyclability ensures that end-of-life car parts made from carbon fiber can be repurposed, contributing to a more circular economy within the automotive industry.

Conclusion:

In the dynamic landscape of automotive engineering, the choice of materials plays a pivotal role in shaping the performance, efficiency, and overall driving experience of vehicles. 3K carbon fiber has emerged as a material of choice for car parts, offering a compelling combination of strength, lightweight properties, durability, and design flexibility.

From improving acceleration and handling to enhancing structural integrity and reducing environmental impact, 3K carbon fiber brings a host of benefits to the automotive industry. As manufacturers continue to innovate and push boundaries, we can expect to see even more groundbreaking applications of this remarkable material in the cars we drive today and those of tomorrow. The journey towards lighter, stronger, and more efficient vehicles is accelerated by the silent strength of 3K carbon fiber, weaving a story of innovation and excellence on the roads ahead.